Redesign of a CT Scanner Outer Frame for Weight Reduction and Structural Integrity

Background

Mobile Stroke Units (MSUs) have changed the way stroke patients are treated by allowing CT scans to be performed directly inside specially equipped ambulances. However, most CT scanners are built for hospitals and are too large and heavy to be used in mobile setups. This project focuses on redesigning the CT scanner’s outer gantry, which is the main frame that supports the rotating parts. The aim is to make the gantry much lighter by using a Carbon Nanotube (CNT) reinforced magnesium alloy (AZ91D + CNT) while keeping it strong, rigid, and safe for use in mobile applications.

Scope of Work

The scope of this research encompassed the complete mechanical design and analysis process for a re-engineered CT gantry structure, from conceptual development through to numerical validation.

The work comprised the following key stages:

Research and Literature Review

Examined existing CT scanner designs, materials, and mounting arrangements used in road-based Mobile Stroke Units (MSUs).

Identified knowledge gaps relating to lightweight structural materials and optimisation techniques suitable for portable medical equipment.

Reviewed the performance and manufacturability of advanced composite materials, with particular focus on CNT-reinforced magnesium alloys for high stiffness and low mass applications.

Implementation of Mechanical Design Stages

Stage 1 – Concept Development: Defined performance objectives (≥25 % mass reduction) and operational constraints based on mobility and structural integrity requirements.

Stage 2 – Preliminary Load Study / Free-Body Diagram (FBD): Developed simplified FBDs to establish loading paths, reaction points, and expected stress regions under gravitational and rotational conditions.

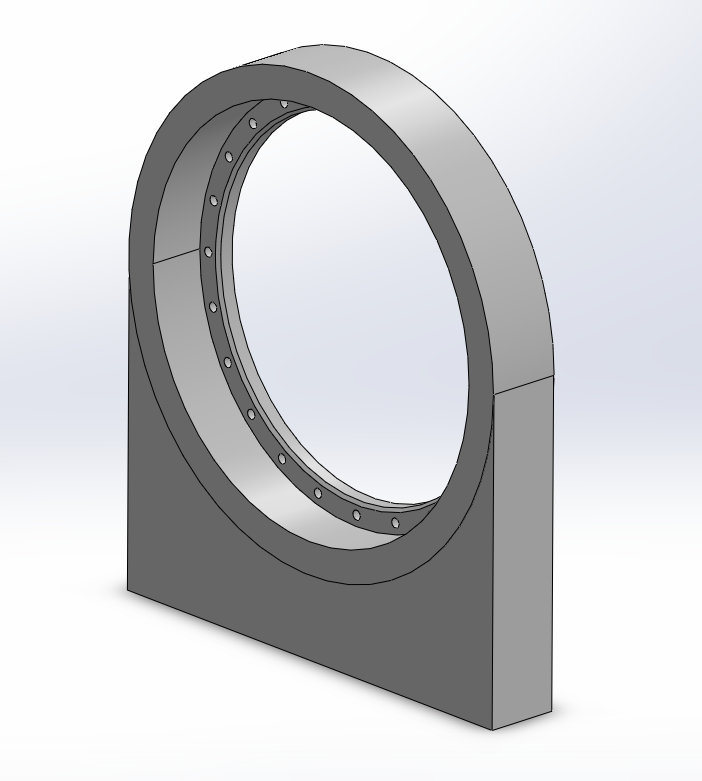

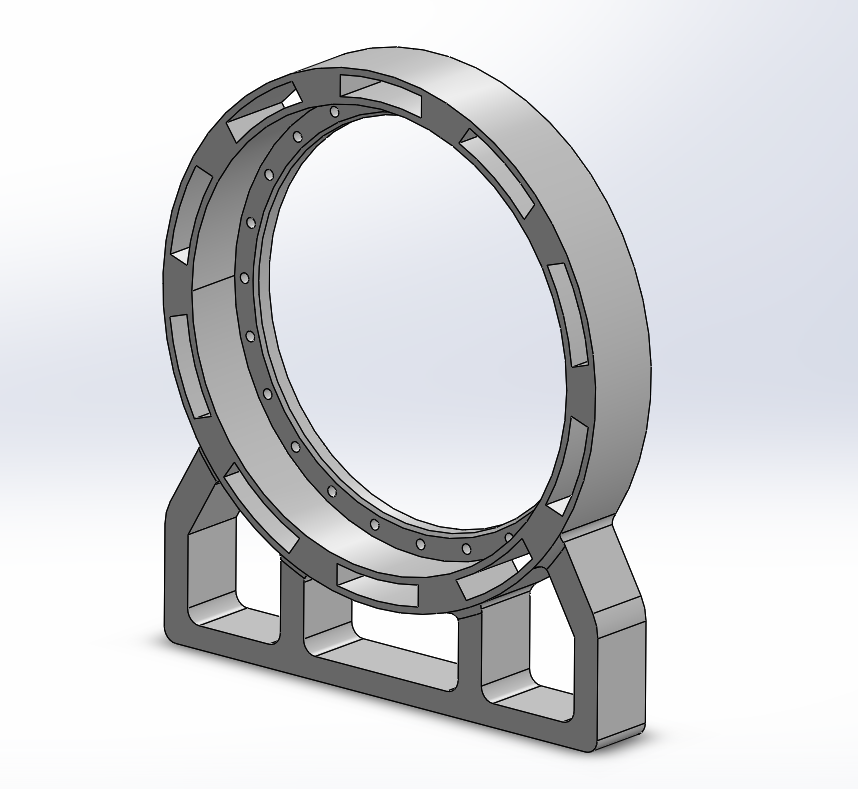

Stage 3 – CAD Modelling: Produced a detailed three-dimensional model of the gantry using SolidWorks, incorporating internal ribs and mounting features to enhance rigidity.

Stage 4 – Topology Optimisation: Applied SolidWorks Simulation with a “best stiffness-to-weight ratio” criterion to eliminate non-critical material zones and improve overall efficiency.

Stage 5 – Finite Element Analysis (FEA): Performed static structural and free-vibration modal analyses using ANSYS Workbench to assess stresses, deformations, and modal characteristics.

Stage 6 – Validation and Material Comparison: Compared AZ91D + CNT and Al 6061 materials in terms of stress distribution, total deformation, natural frequency, and overall mass reduction.

Scope Limitation

This study was restricted to static and modal (free-vibration) analyses only.

The effects of dynamic loading, such as transient vibrations, harmonic excitation, and rotational imbalance, were not considered within the scope of this work and are recommended for future investigation.

Material Study

The use of Carbon Nanotube (CNT) reinforced magnesium alloy (AZ91D + 3 wt%) was investigated as a potential replacement for conventional aluminium alloys.

CNTs possess a Young’s modulus of ~1 TPa and excellent load transfer capability, significantly improving the strength and stiffness of the magnesium matrix.

Results Summary

Discussion of Realism

The obtained results are realistic and consistent with magnesium-based composite behaviour under moderate loading.

Maximum von Mises stress: 4.44 MPa, well below the material yield (284 MPa); indicates a safe and conservative design.

Total deformation: 0.09 mm, confirms high stiffness and dimensional stability.

First natural frequency: 58 Hz, within the typical CT gantry range (40–60 Hz), validating model accuracy.

The applied static load of 3.5 kN (~357 kg) realistically represents the distributed operational load on the gantry.

Only static and modal (free-vibration) analyses were performed; dynamic and harmonic effects such as road vibration (2–20 Hz) and rotational imbalance were not included.

As the first natural frequency lies well above road-induced frequencies, resonance is unlikely under normal operating conditions.

Fabrication challenges for CNT-reinforced magnesium alloys include:

Difficulty in achieving uniform CNT dispersion due to agglomeration.

Ensuring strong interfacial bonding between CNTs and the Mg matrix.

Preventing oxidation of magnesium during processing.

Manufacturing processes such as semi-powder metallurgy or spark plasma sintering (SPS) require precise control of temperature and pressure to preserve CNT integrity.

Overall, the results are credible, and the design meets stiffness and weight-reduction targets; further experimental validation and dynamic testing are recommended.